Red Jacket Product Guide

Our comprehensive Red Jacket® Product Guide highlights our complete Red Jacket Product Portfolio and covers considerations for pump selection, ordering, and more.

Explore the guideRed Jacket® Submersible Turbine Pumps

Easy to Install

Fixed speed technology cuts down installation costs and avoids electrical interference with your ATG, POS, Cameras, and Intercoms. Red Jacket Pumps also feature an integrated yoke and junction box, eliminating the need for external components and further streamlining the installation process.

Easy to Service

The Red Jacket STPs include multiple features to ensure that they are easy and safe to service. This includes easy line isolation and testing, automatic electrical disconnect and fuel drain, and isolated and integrated contractor's box and capacitor housing.

Global Safety Certification

The Red Jacket portfolio of submersible turbine pumps contains a variety of solutions to comply with global standards and are recognized by all major regulatory bodies.

Unmatched Support Network

Known for their quality and reliability, Red Jacket STPs are installed and serviced across the globe. Red Jacket products receive the highest level of support from our team of authorized service contractors and service providers.

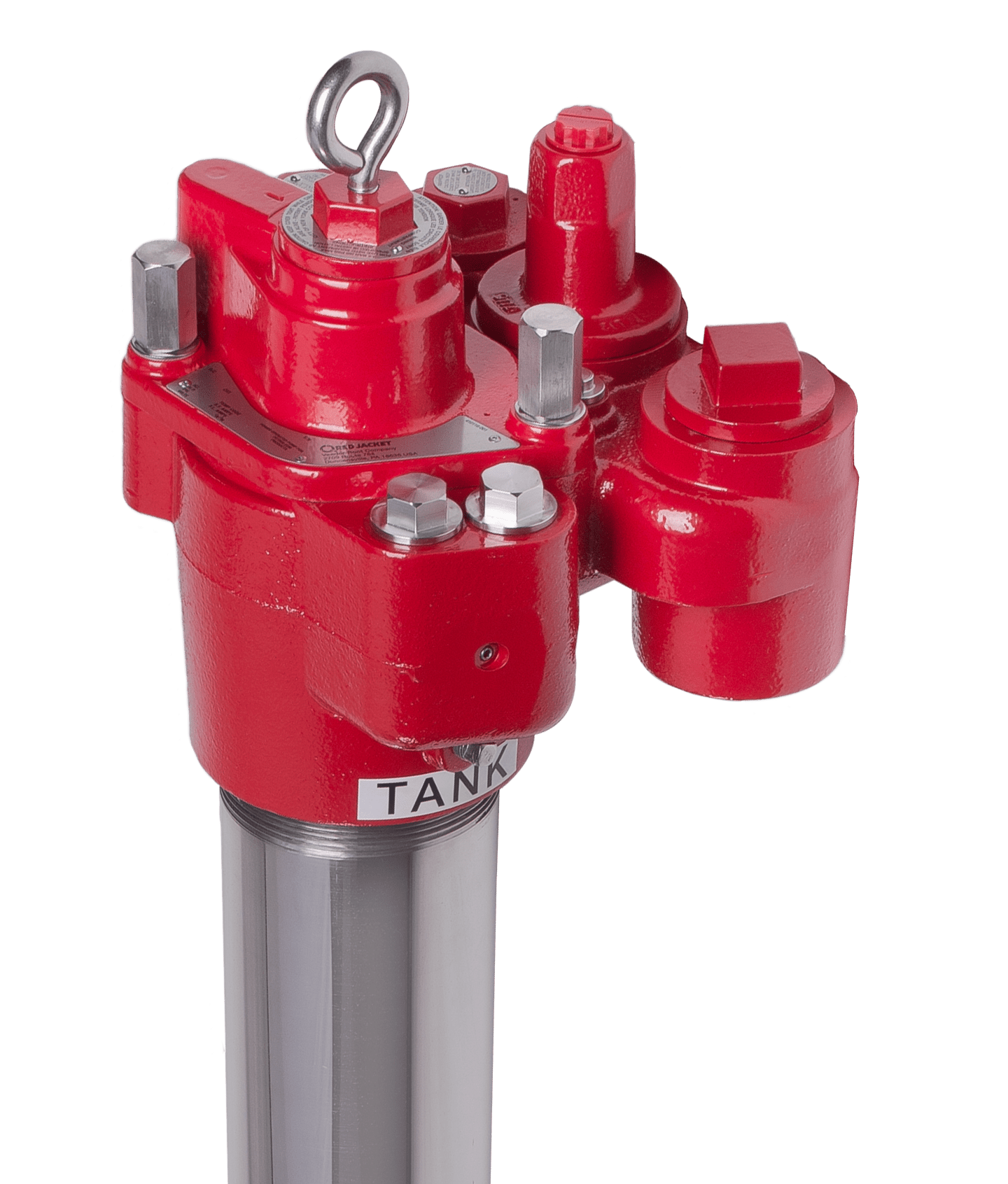

The Red Jacket 4" STP Models

Built to Last

The demand for higher fuel flows and lower power consumption while maintaining flexibility for service, drove the development of advanced packer and motor designs on all The Red Jacket STP models.

Built for Biofuels and Blends

The increased presence of alcohol gases in fueling applications have triggered a change in the pumps needed to handle harsh conditions.

Built to Combat Corrosion

A specialty coating on the manifold and discharge head that withstands acetic acid exposure to prevent corrosion and pitting to the cast iron surface over time.

High Flow Rates Using Less Power

The Red Jacket Submersible Turbine Pump (STP) platform delivers fast, reliable fuel flow for the lower cost of ownership.

LEARN MORE ABOUT THE RED JACKET 4" STP PLATFORMLogistics Optimization using Advanced Controls

Flow Optimization

Monitor demand at the site and stage on additional pumps to ensure optimal fuel flow at all demand conditions.

Intelligent Pump Control

Gain real-time visibility regarding the performance of your Red Jacket STP, make informed maintenance decisions, and ensure efficient service calls. Intelligent Pump Control (IPC) Software with Red Jacket Diagnostics runs on the TLS-450PLUS Automatic Tank Gauge (ATG), and communication flows between the ATG and STP through the IQ Smart Control Box.

System Redundancy

Manifold two Red Jacket STPs at sites with high throughput to increase flow rates and add redundancy.

Inventory Optimization

The Red Jacket IQ Control Box, ISOTROL™ 1-8 Relay Box, and TLS-450PLUS Automatic Tank Gauge combine to create the flexible Virtual Siphon solution that gives users multiple settings for dispensing fuel from the tanks.

Learn MoreCombat Corrosion in Sump Spaces

Corrosion of equipment in sumps causes deterioration and shortens its useful life span. As corrosion advances it has the potential to affect the integrity of piping and electrical systems, and the serviceability of STP equipment.

Liquified Petroleum Gas Premier STPs

The Premier series is designed with a sleek and safe profile, supporting flexible applications and sufficient protection to comply with local safety regulations. With the Premier Series, Red Jacket is proud to introduce the only LPG solution capable of supplying multiple dispensers with exceptional flow rates simultaneously.

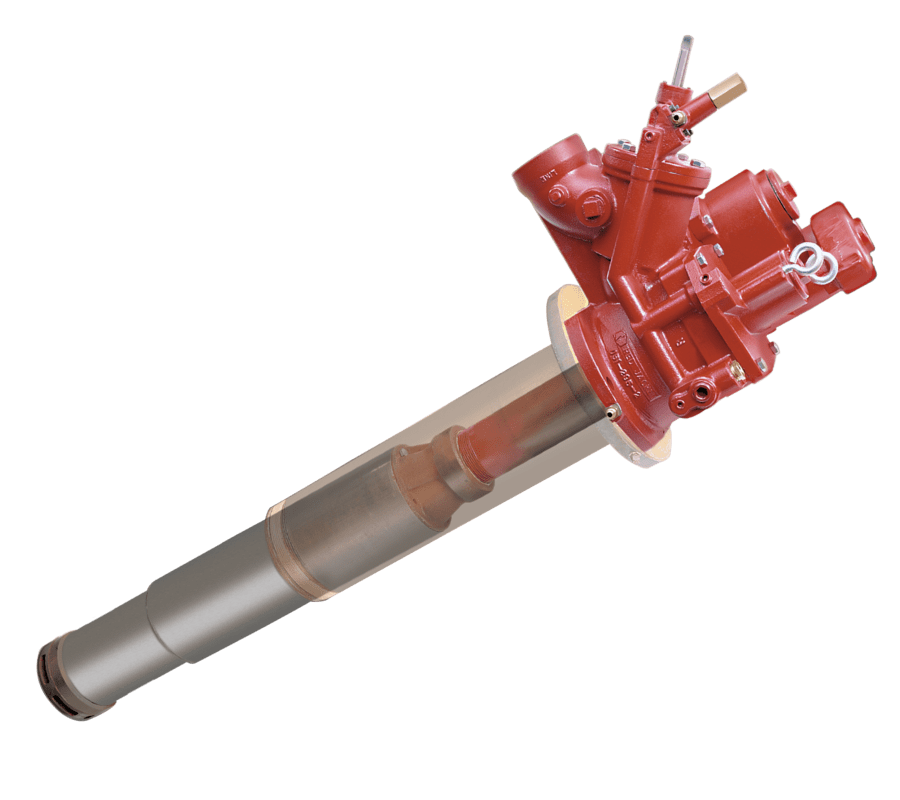

Explore the principles of LPG handlingMaxxum 6" Submersible Turbine Pump

The Maxxum STPs and Unitized Motor Pumps (UMPs) provide the industry’s highest flow rates by reducing the number of restrictions within the flow path. The efficient design also leads to less power consumption, contributing to a lower lifetime cost of operation. Easy access to valves and ports allows for reliable diagnostics and fast service.

Learn More